10/11/21 – The epoxy continues

Waits while epoxy cures

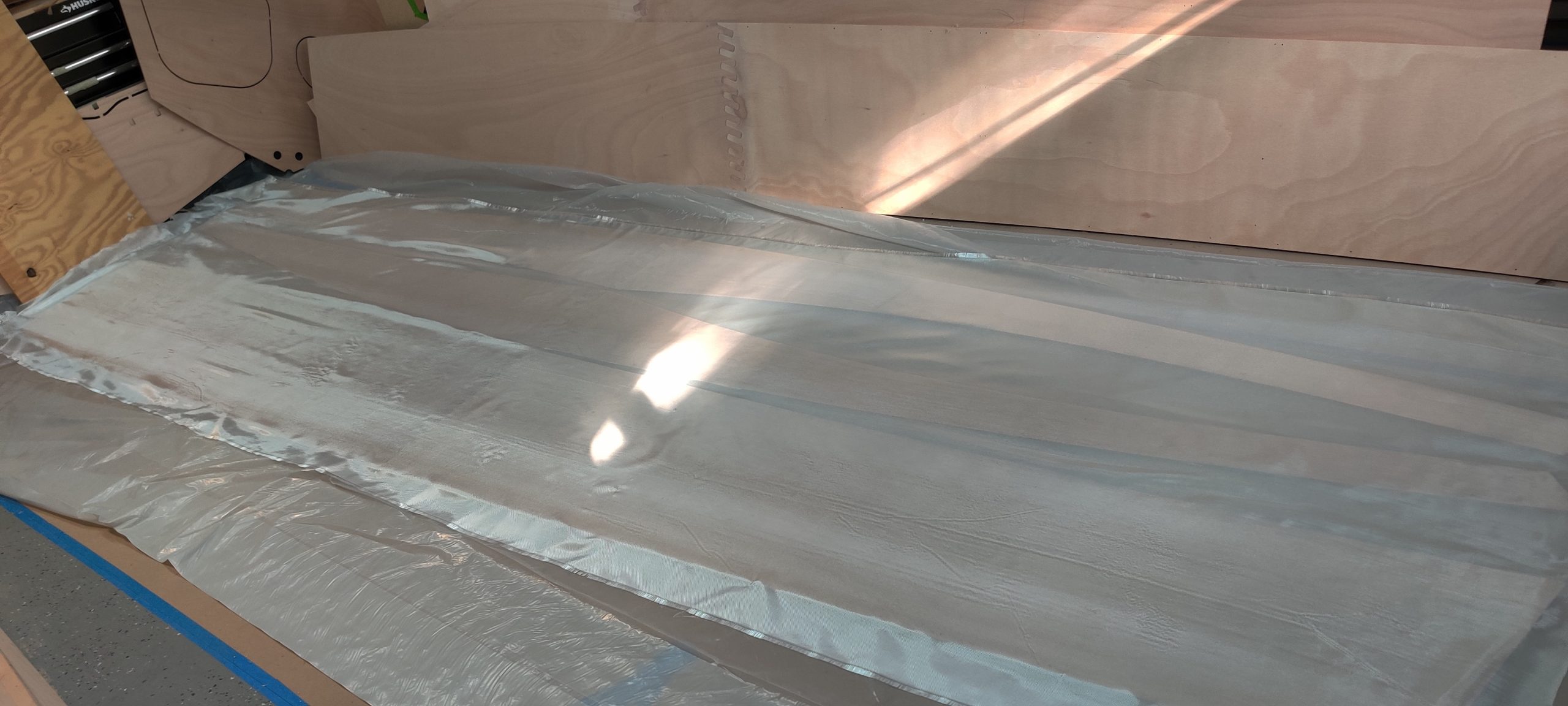

Progress has slowed as expected during the glassing stage of the PocketShip hull panels while waiting for several layers to cure. I am at 3 light coats of epoxy with a leveling sand after the second. The wait time has been longer to avoid gumming up the sanding disks and will allow for a more complete cure with the final. I have moved onto smaller batches for the fill coats and moved to fast cure hardener in a higher ratio. The slower curing, low viscosity mix is much better at soaking into the wood and helping to strengthen the bond. The fill coats that hide the glass weave strengthen the overall structure but help provide the smooth surface for a glistening paint job or leaving bright with just varnish.

Why do we laminate things before assembly?

Why do we not laminate all the pieces while we do that for some of them? Some panel faces are MUCH easier to reach, particularly when they are on the outside of the hull. Sanding takes time and is much harder is restricted spaces. I am getting several areas paint ready or nearly so before assembly to reduce the stress of sanding in random gymnastic poses and fighting gravity. At least one layer of glass on the joined pieces also helps to reduce the stress on the puzzle joints. I would love to get a layer of glass on everything but the bond of epoxy and glass to wood can be much stronger than epoxy to epoxy.

A suggestion

If you will be glassing on the floor like I did here, do yourself a huge favor and get some knee pads. I ended up grabbing some of my skateboarding knee pads after much pain from walking around on the knees while glassing. They are damaged enough from cycling and football as it is. Kneecaps on concrete for an extended period of time is just bad. I will be looking for a pair of gel kneepads that are lower profile as I could probably deflect 2x4s with the ones I have. They also hold heat in like a champ. For future glassing I’ll be moving to 2 sets of sawhorses since the panels have too much flex and a 15-16 ft table or workbench isn’t happening here.

Looking forward with the PocketShip build

This week at work will be another one of long hours and reporting. I am expecting the progress to continue slowly but do have hope of starting assembly in the cradle by the weekend. Last night I just stood in the garage watching the light reflect off of the panels realizing that they will not be flat for much longer.

I also have been adding some coats of epoxy to the floor supports and will be sanding those smooth to get them ready for installation. Sometimes pictures of epoxy curing is just that, epoxy curing.