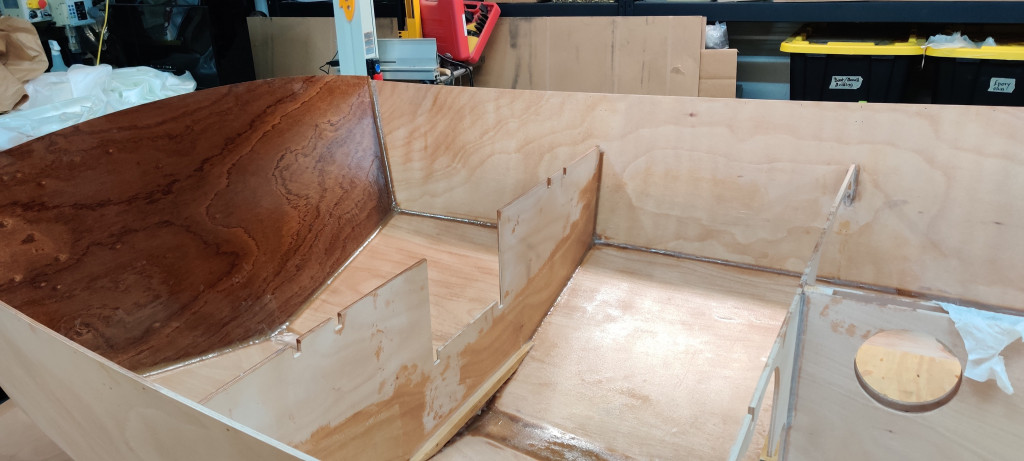

11/4/21 – It’s the bilge

I’m still glassing the lower inside hull and it gets a little tight within the bilge – the work week/allergies/down time has limited my work range but I try to get at least one section down every night.

Slow and steady

This process slowed me down a bit but I rather let the epoxy cure and get a quick fairing of the edges before laying the next adjacent layers down. This makes for a smoother layering and less epoxy and sanding is needed as a result. Time = less epoxy and less sanding.

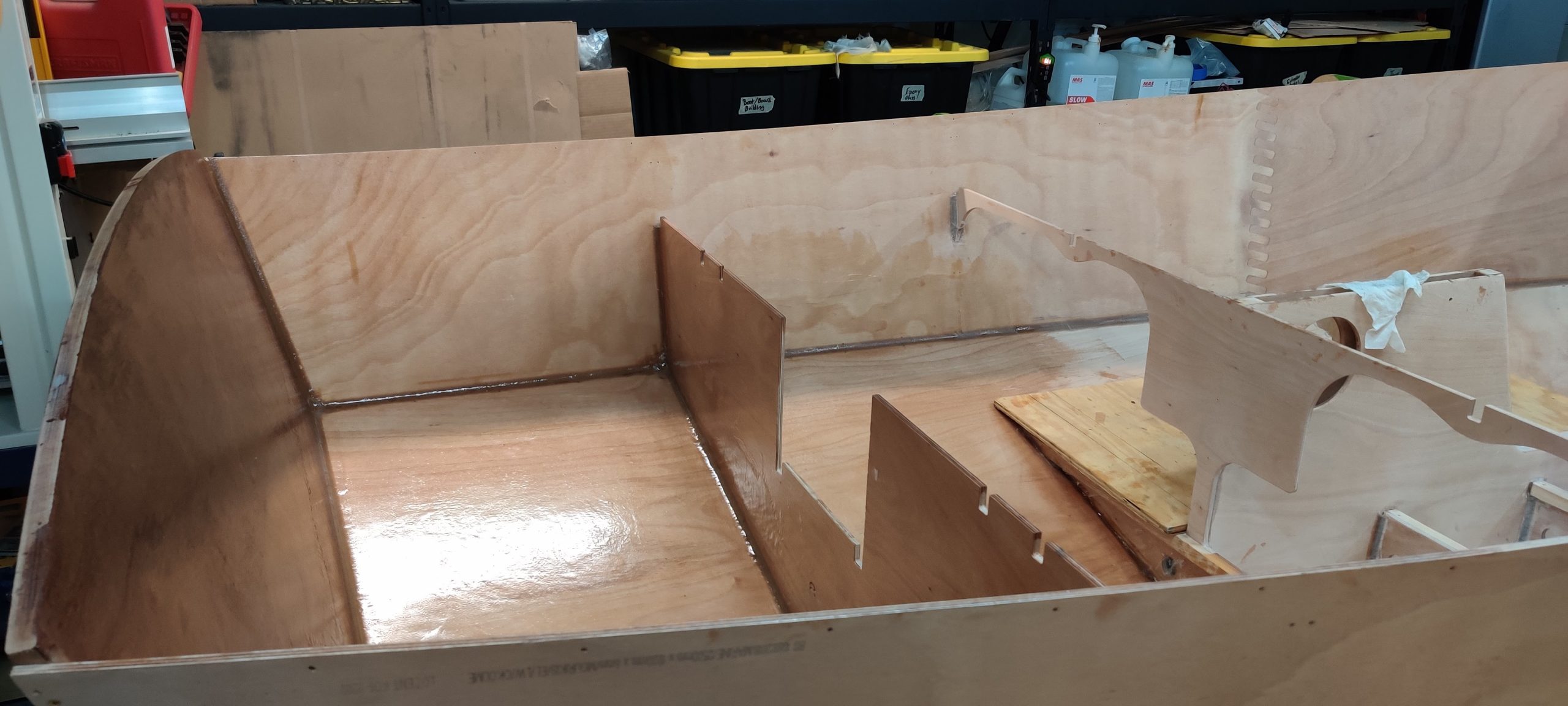

I also ordered 1″ garboard drain plugs with flanges to add drainage to the front and rear compartments emptying to the bilge in the unlikely infiltration of water. Waterproof cable glands are arriving tomorrow for the nav lights, power running from gen/inverter on the outboard, and anything else leading to those compartments. The quick disconnect 4 pin connector and receiver arrived yesterday for the mast connections.

I picked up paint for the interior yesterday with the intention of having that ready as soon as the inside final epoxy coats and fairing are complete. I will start wiring runs at that point before I start on the floor layout to determine the exit points and routing more simply.